We appreciate your interest in our story. It is something we are really proud of. An interesting topic, a special environment. The people in charge are successful professionals. The plot is situated here in Darmstadt but also takes place in Europe. It could be realized anywhere – in your region maybe?

Portfolio: Varian Medical Systems

OUR FOCUS - YOUR SUCCESS

FOREWORD

We are often asked about our special expertise in terms of a particular field of knowledge. In the development of medical and diagnostic devices, however, we constantly deal with new challenges. Therefore, there is no such thing as a ready-to-use set of applicable competences and know-how.

Our key to success: the flexible use of what we know in new contexts. Our engineers have a wide and solid know-how gained from many fields of application.

They get in contact with what our customers know and make use of it in the ongoing project. For this kind of know-how transfer, we sometimes also acquire highly-specialized expertise from science and research.

For the creation of excellence, you have to gather the best around you. Each of us knows SOMETHING, and we additionally know HOW.

Together, we develop medical devices that change the world. We solve today’s problems with the help of tomorrow’s technology. This is really encouraging and helps push the limits. That’s what we do.

A NEW CHALLENGE

A clinic in Delft (Netherlands). The plan is to establish the first unit worldwide for the treatment of eye cancer.

Rare diseases demand new treatments and capable medical devices. Surgical procedures can be risky.

There is hope in innovative treatment concepts. Being able to destroy tiny tumors with the precision of proton beams without harming the surrounding tissue would allow for more safety and keep the patient’s eyesight. A worthwhile project improving the lives of many patients.

A SUCCESSFUL PARTNERSHIP

Using proton beams in cancer treatment is a highly-specialized field. VARIAN is an expert here.

Varian Medical Systems from Palo Alto, California, USA develops complete hardware and software systems for radiation therapy.

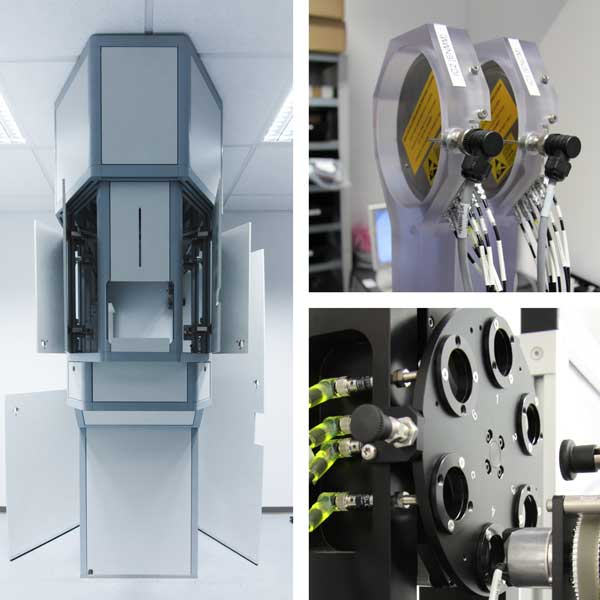

A health company with multinational business relations. Know-how in tumor therapy that is based on long-term experience. Numerous clinics and health centres worldwide operate VARIAN devices. The device unit in question consists of a proton accelerator and several connected treatment rooms. The whole unit is both, technically and economically highly efficient.

Mechatronic’s project order: developing and manufacturing the first proton beam unit for the tumor treatment of the eye and preparing it for operation in a regular clinic environment in the Netherlands.

PROFESSIONAL PROJECT START

Starting signal for the transfer of know-how in interdisciplinary workshops. Our project team consists of system architects, software engineers, electronics engineers, mechanics, quality managers – each of them up-to-date, knowing their trades and guided by capable leadership.

Within a week, the first system concepts are ready, risks have been identified, the FMEA has been prepared. The complex device unit is being viewed from several angles, the know-how of all participants is included. Nothing remains unseen in this critical phase, and every detail is on the agenda. Everybody knows what to do. In this team process, every challenge finds its solution.

QUALITY MANAGEMENT WITHIN THE CUSTOMER’S SYSTEM

The key components of our project start are the integration of know-how and the efficient fusion of teams.

As a third success factor, we carry out the documentation within our customer’s quality management system. Our engineers used VARIAN’s documentation environment in order to document each individual step of the development. At the end of the day, the proton device is expected to operate in a high-performance clinical setting.

For the Darmstadt crew this meant: installing the IT systems at the customer’s site, access to the VARIAN environment, training and diligent adaptation to the required standards. It is a complex challenge to master different system environments at the same time. That is why we rely on only the best in their trades.

MILESTONE MEETINGS

Starting off on the right foot is just as important as monitoring the project along the way. At Mechatronic, we rely on milestone reviews.

We know what the time-cost-quality frame really means. We achieve the defined goals by applying tight time plans and quick decisions.

What our meeting culture is made of at Mechatronic: competences needed in each of the fields on equal terms, no matter whether technical, time-related or financial, the participation of stakeholders, and the rapid realization of decisions made. With all our complex projects we have come to appreciate stage-gate-processes. Our VARIAN project once again proved that technical mastery on the system level goes hand in hand with the team component on the project management level. This is how we work. We are experts in both of these fields and many more.

FOIK – FIRST OF IST KIND

It really is special to be first in any given discipline. In the VARIAN case, it was the proton beam for the treatment of eye cancer.

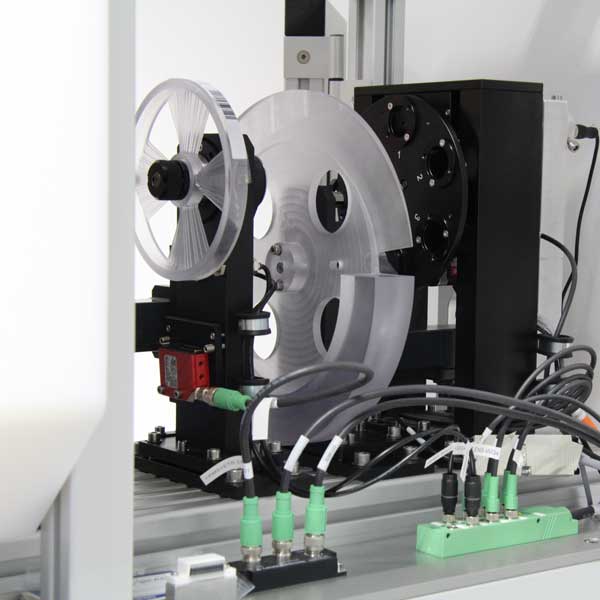

We were in charge from the first “no one has ever done that” to “works in a clinical environment”. We are especially proud of our FOIK – the first of its kind. A single unit made to specification and the first masterpiece of this project. Starting with the beam modulation which in itself required complex mechanics. Individually manufactured components interactively control the intensity and depth of the beam effect on the patient. The concentrated energy of the proton beam exactly hits the treatment mark of the eye.

Hitting the mark is the target in focus. When it comes to the treatment of the eye, patient safety is eminent. It all depends on the safety system, our second masterpiece. In order to ensure the patients’ safety, we utilized everything that is technically feasible. All safety features were equipped with redundancies. Data from several measuring methods were constantly matched. We set up parallel monitoring and safety systems for real-time use.

Strict requirements were realized in the video monitoring of the eye position. All components and installations were built and tested on a made-to-specification prototype. The installation of the FOIK ran smoothly, too, and topped off our development process.

AUTOMATED TESTING

Does the investment of an automated testing system always pay off? From the developer’s point of view, the answer is “Yes”.

In the VARIAN case it did pay off. The testing system was almost ideally applied.

All electric interfaces between device, monitoring, safety and managing systems were separated for the assembly of the prototype so that the bi-directional data and signal flow was enabled on all lines. Thus, all system signals and data packages could be received, analyzed, redirected and simulated. We were able to test the responding performance of individual components in all settings. This was especially important for testing the patient-related safety and switch-off features which have to function flawlessly in real situations.

And what’s even better: in the VARIAN project, system changes could be tested overnight with the help of complete cycles of regression testing. Test results were available the following morning so that the development continued without delay. The “hardware-in-the-loop” method does not only save time and costs, it also makes the systems undergo supervised learning-cycles, which provides us with valuable data.

INSTALLATION, AUTHORIZATION AND INITIAL OPERATION

Just as exciting as its start: the final stage of the project.

Our engineers deliver the device with all the development results and documentations. As we worked within the customer’s development and quality environment only, VARIAN had the benefit of total transparency regarding the technical documentation within their own system.

For the installation, verification and validation in the Delft clinic, a Mechatronic team accompanied the FOIK on its way to its destination. The installation within the clinical environment was monitored in cooperation with our customer.

A moment of triumph and reflection: with this act of initial operation the project was successfully completed for all parties involved. Endurance test passed in reality. Vision technically realized. Successful team cooperation and efficient project management, just as we are accustomed to perform. Still, we take a quiet moment to marvel at what is possible in medical engineering.

POSTSCRIPT

Of course, we are proud of helping medical progress become reality with our technical expertise. It was indeed the first development, authorization and initial installation of a device for eye tumor proton beam treatment in a regular clinical environment worldwide and a real success, too. Unique as the only of its kind. Maybe other projects will follow this example with similar impacts.

We would like to thank both project teams for their excellent professional performance in this very special project. Together, it was possible to realize a complex project within the given time-cost-quality frame.

Special thanks go to our customer VARIAN for the opportunity to publish this success story.